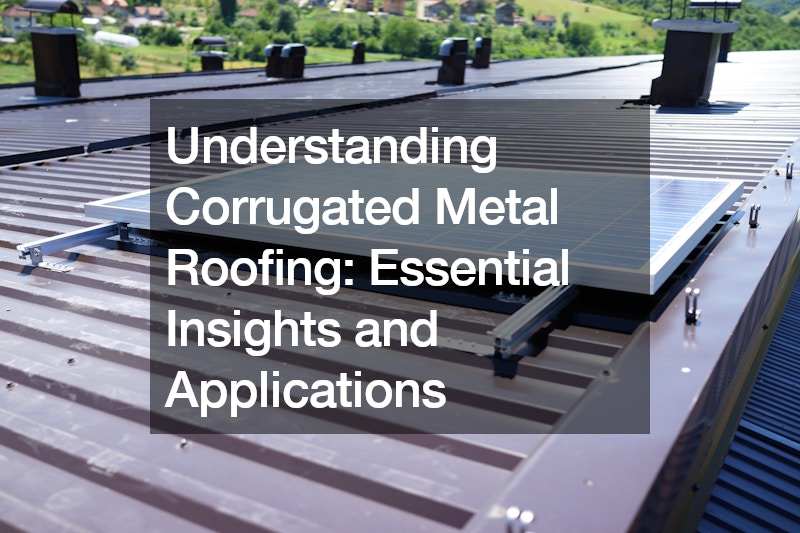

Corrugated metal roofing has been a staple in the construction industry for over a century. Known for its distinctive wavy or rippled pattern, this type of roofing offers a range of benefits, including durability, versatility, and aesthetic appeal. This article delves into the essential insights and applications of corrugated metal roofing, highlighting its history, materials, and practical uses.

History of Corrugated Metal Roofing The history of corrugated metal roofing dates back to 1829 when Henry Robinson Palmer, an architect and engineer for the London Dock Company, patented corrugated iron. This innovation quickly gained popularity due to its strength, corrosion resistance, and ease of transportation.

By the 1890s, wrought iron was replaced by steel, further enhancing the durability and applicability of corrugated panels in construction.

Manufacturing Process: Corrugated metal roofing is produced through roll forming. Sheet metal is passed through a series of dies, shaping it into the desired corrugation. This process strengthens the metal and gives it its characteristic wavy pattern. The most common materials used for corrugation include coated carbon steel, stainless steel, aluminum, and copper. Non-metal materials such as plastic and fiberglass are also corrugated for various applications.

Materials Used Coated Carbon Steel Coated carbon steel is one of the most popular materials for corrugated roofing. It combines the strength of carbon steel with a protective coating, which enhances its resistance to rust and corrosion. This makes it ideal for both residential and commercial applications where durability is paramount.

Stainless Steel offers superior corrosion resistance and strength, making it suitable for harsh environments. Its sleek, modern appearance also adds a contemporary touch to buildings, making it a favorite choice for architectural projects.

Aluminum Aluminum is lightweight, resistant to corrosion, and easy to work with, making it an excellent material for corrugated roofing. Its reflective surface can help reduce energy costs by deflecting sunlight and heat away from the building.

Copper Copper, while more expensive than other materials, provides a unique aesthetic appeal with its distinctive patina over time. It is also highly durable and corrosion-resistant, making it a long-lasting option for premium projects.

Applications of Corrugated Metal Roofing Corrugated metal roofing is highly versatile and can be used in various applications beyond roofing. Here are some key uses:

Roofing Corrugated panels are widely used for roofing due to their durability, weather resistance, and ease of installation. They are suitable for residential homes, commercial buildings, and industrial structures. The overlapping installation method with exposed fasteners ensures a secure and leak-proof roof.

Siding Besides roofing, corrugated metal panels are commonly used. They provide a robust barrier against the elements and can enhance the visual appeal of a building with their unique texture and pattern.

Decking and Flooring Corrugated metal panels are also used in decking and flooring, particularly in industrial settings. Their strength and durability make them an excellent choice for areas that require a sturdy, long-lasting surface.

Prefabricated Structures The lightweight nature of corrugated metal makes it ideal for prefabricated structures. These panels can be quickly and easily assembled, making them perfect for temporary buildings, sheds, and other modular constructions.

Benefits of Corrugated Metal Roofing Durability One of the most significant advantages of corrugated metal roofing is its durability. The corrugation process strengthens the metal, making it resistant to impacts, heavy loads, and extreme weather conditions.

Corrosion Resistance Corrugated metal panels offer excellent corrosion resistance, especially those made from stainless steel, aluminum, and coated carbon steel. This ensures a longer lifespan, even in harsh environments.

Aesthetic Appeal The distinctive wavy pattern of corrugated metal roofing adds a unique visual element to any building. Whether used for roofing, siding, or decorative purposes, it can enhance the overall aesthetic of a structure.

Energy Efficiency Certain materials like aluminum reflect sunlight, helping to keep buildings cooler and reducing the need for air conditioning. This can lead to significant energy savings over time.

Eco-friendly metal roofing is often made from recycled materials and is recyclable at the end of its lifespan. This makes it an environmentally friendly choice for construction projects.

Conclusion Corrugated metal roofing remains popular in the construction industry due to its numerous benefits and versatile applications. From its historical origins to its modern-day uses, this roofing offers durability, aesthetic appeal, and practicality. Whether you are considering it for roofing, siding, or any other application, understanding the essential insights and benefits of corrugated metal roofing can help you make an informed decision for your next project.

.